CAM

Home » Collaborative Design » CAM

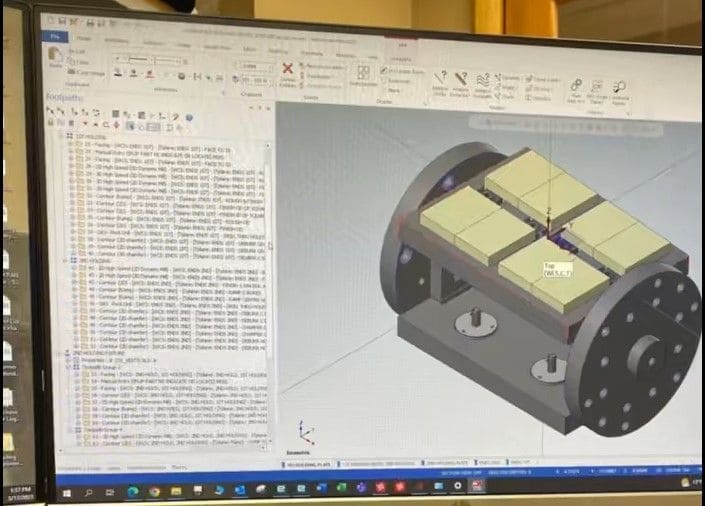

CAM Services – Precision Programming for Efficient Manufacturing

At DSI Manufacturing, we know that great manufacturing depends on more than just skilled machining or fabrication — it starts with accurate, efficient programming. Our CAM (Computer-Aided Manufacturing) services bridge the gap between your CAD designs and real-world production, ensuring parts are machined, cut, and formed with maximum precision and efficiency. With over 40 years in sheet metal fabrication, CNC machining, assembly, and finishing, we bring deep manufacturing expertise to every CAM program we create. Our programmers work directly with our engineers and machinists to ensure each toolpath is optimized for speed, accuracy, and quality.What Is CAM and Why It Matters

CAM is the process of converting 3D CAD models into machine-readable instructions for CNC mills, lathes, lasers, and other manufacturing equipment. A well-crafted CAM program:

- Maximizes machining efficiency and throughput

- Extends tool life and reduces maintenance costs

- Ensures consistent part quality and tight tolerances

- Minimizes waste by optimizing material usage

- Shortens lead times by eliminating trial-and-error on the shop floor

Poor programming can lead to scrap, rework, and delayed deliveries. That’s why our CAM team is fully integrated with our production floor — so your parts are right the first time.

Our CAM Capabilities

1. CNC Programming for Milling and Turning

We develop programs for a wide range of CNC equipment, from 3-axis vertical mills to advanced 5-axis machining centers and CNC lathes. This includes:

- 3-axis, 4-axis, and 5-axis milling toolpaths

- Live-tool turning operations

- High-speed machining strategies

- Complex surface and contour milling

2. Laser Cutting and Sheet Metal CAM

For precision sheet metal fabrication, our CAM software generates optimized laser cutting paths that minimize pierce points, reduce cycle times, and nest parts efficiently to save material.

3. Toolpath Optimization

We carefully analyze each toolpath for:

- Shortest machining time without sacrificing quality

- Minimized tool changes

- Balanced cutting forces to maintain dimensional accuracy

- Reduced non-cutting air moves

4. Simulation and Verification

Before a program ever reaches the machine, we simulate the entire process in our CAM software to:

- Check for collisions and tool interference

- Verify feed rates, spindle speeds, and cutting parameters

- Ensure correct tool selection and setup

- Confirm part dimensions match the CAD model

5. Integration with CAD

Our CAM team works hand-in-hand with our CAD engineers to make sure every design is fully manufacturable. This collaboration reduces back-and-forth, shortens setup time, and ensures your part is right from design to production.

From Programming to Production – The DSI Workflow

- CAD Design – Initial part modeling and DFM review

- CAM Programming – Toolpath creation, simulation, and verification

- Machine Setup – Precise fixture and tooling alignment

- Production – CNC machining, laser cutting, forming, and finishing

- Inspection – ISO 9001:2015-certified quality control

By managing the entire process in-house, DSI ensures your CAM programs translate into efficient, high-quality production runs every time.

Industries We Serve with CAM

- Medical – Precision housings, surgical instruments, and equipment parts

- Electronics – Enclosures, chassis, and mounting components

- Automotive – Brackets, custom hardware, and precision-machined parts

- Retail Fixtures – Fabricated and finished displays ready for assembly

- Construction & Industrial – Control boxes, safety guards, and machine components

- Energy & Agriculture – Rugged field-ready parts

Quality Assurance in CAM

Our ISO 9001:2015 certification applies from programming through final inspection. We validate:

- Dimensional accuracy and tolerance compliance

- Correct tooling and fixture selection

- Optimized feeds and speeds for material type

- Elimination of potential collisions or tool wear issues

Benefits of Partnering with DSI for CAM

- Optimized Efficiency – Faster cycle times and reduced machining costs

- Consistent Quality – Verified programs that meet exact specifications

- Integrated Process – Seamless transition from CAD to CAM to production

- Material Savings – Nesting and path strategies that minimize waste

- Scalability – From one-off prototypes to high-volume runs

CAM FAQs

Can you work with my CAD files?

Yes. We import industry-standard CAD formats such as SolidWorks, AutoCAD, STEP, and IGES directly into our CAM software.

Do you optimize for specific materials?

Absolutely. We adjust feeds, speeds, and tooling based on whether your part is aluminum, stainless steel, carbon steel, or plastic.

Can CAM help reduce my lead time?

Yes. By eliminating trial-and-error on the shop floor and running fully verified programs, we shorten production times significantly.

Do you handle both milling and turning CAM?

We program for both milling and turning operations, including multi-axis and live-tool setups.

Let’s Optimize Your Production

Whether you need complex 5-axis machining programs or efficient sheet metal nesting, DSI’s CAM services ensure your designs are manufactured quickly, accurately, and cost-effectively. Our integration of CAD, CAM, and full in-house manufacturing means you get better results in less time.

Contact us today to see how our CAM expertise can help streamline your next project from programming to production.