Collaborative Design

- Home

- Collaborative Design

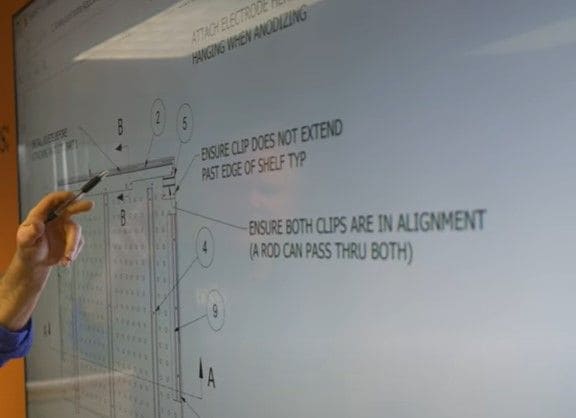

Collaborative design plays a pivotal role in sheet metal fabrication manufacturing, fostering innovation, efficiency, and precision by bringing our customers and engineers together to ensure our customers’ needs are being met. Collaborative design ensures that part designs are not only manufacturable within the constraints of sheet metal processes but also within the specifications our customers require.

Furthermore, collaborative design minimizes costly revisions and errors. By working directly with our customers from the outset, potential design flaws and manufacturability issues are identified and addressed early in the process.

This proactive approach saves both time and resources, allowing for smoother project execution. This approach also results in cost savings and reductions in lead times because our engineers can optimize the use of materials, reduce waste, and enhance the efficiency of manufacturing processes.

Ultimately, collaborative design within sheet metal fabrication manufacturing fosters a culture of innovation, teamwork, and continuous improvement. It ensures that the end products meet or exceed quality standards while increasing efficiency and reducing lead times.

Design for Manufacturability

Design for Manufacturability (DFM) in sheet metal fabrication is a strategic approach that focuses on optimizing product designs to streamline the manufacturing process.

Value Engineering

Value engineering (VE) maximizes the value of a product while minimizing costs. In this process, our team of engineers and subject matter

Prototyping

Creating a prototype can be a time-consuming process. At DSI, our job is to help you succeed as quickly and efficiently as possible.

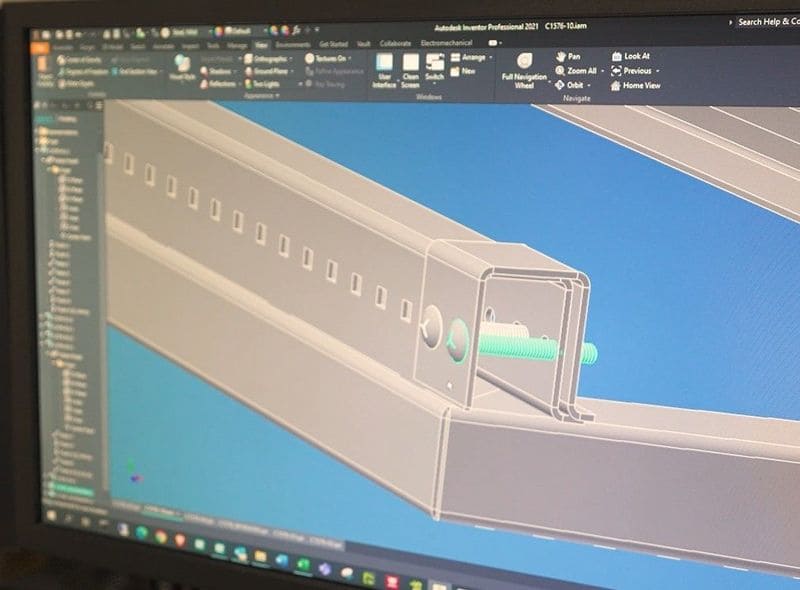

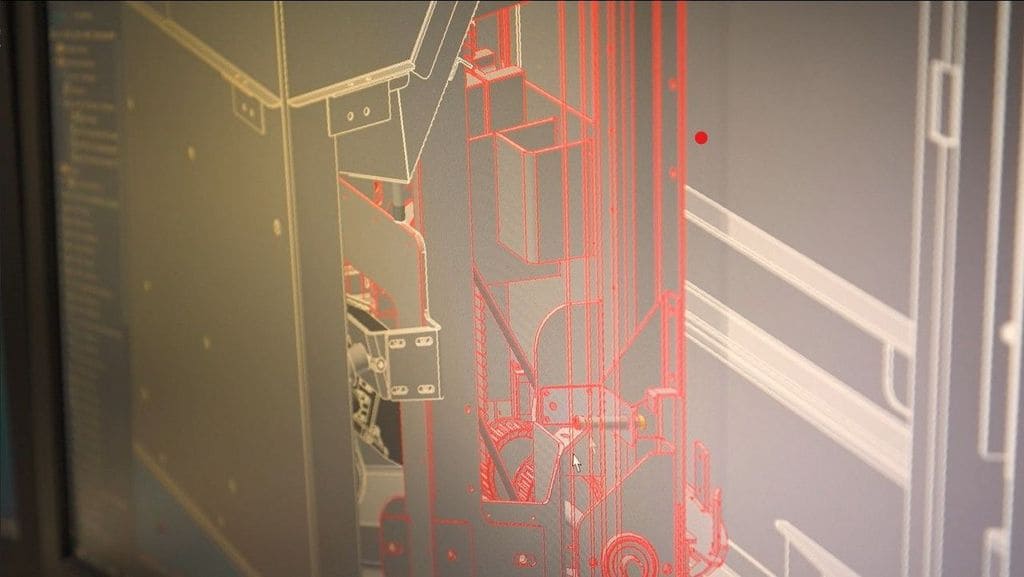

CAD

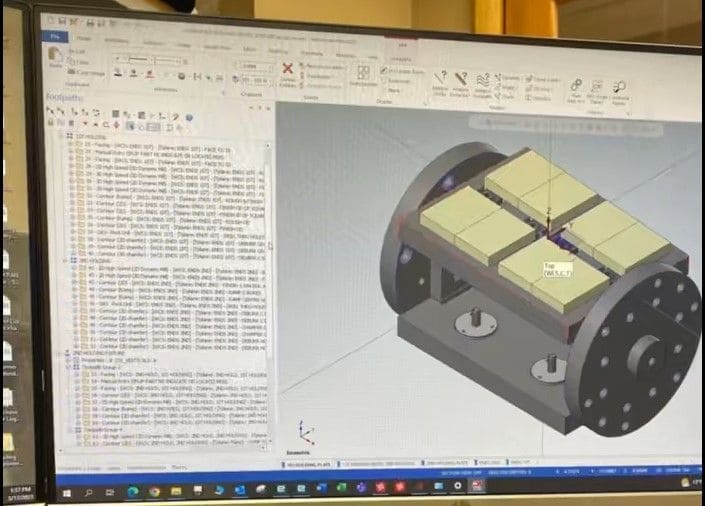

Computer Aided Design, also known as CAD, allows the engineers to digitally develop, edit, modify, and optimize or improve the design and quality of your parts.

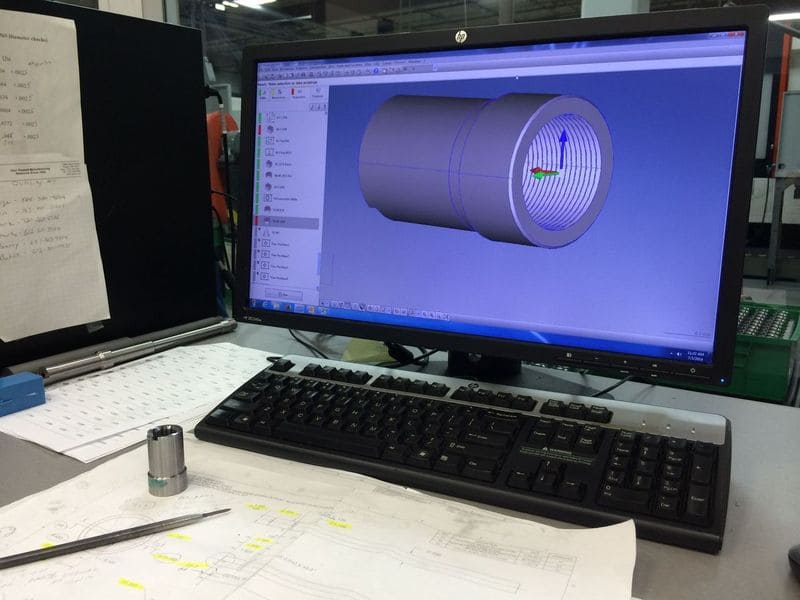

CAM

Computer-Aided Manufacturing (CAM) is a crucial component of modern manufacturing processes. It involves the use of computer software and technology.