CAD

Home » Collaborative Design » CAD

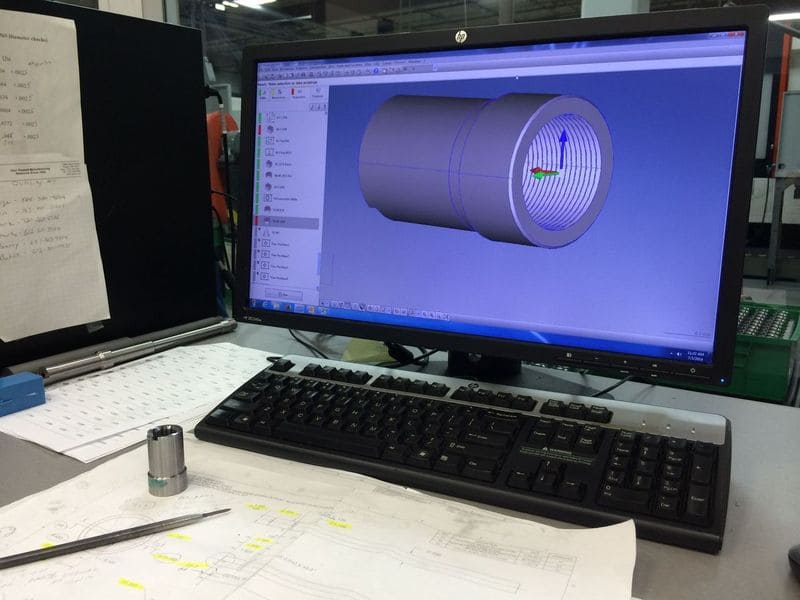

CAD Services – Collaborative Design & Engineering for Precision Manufacturing

At DSI Manufacturing, great manufacturing starts with great design. Our CAD services lay the foundation for efficient, cost-effective, and high-quality production. Whether you are refining an existing concept or starting from scratch, our team works with you to turn ideas into manufacturable, market-ready products.

With over 40 years of experience in precision sheet metal fabrication, CNC machining, assembly, and powder coating, DSI brings a complete, in-house perspective to the design process. That means every part is engineered for performance, manufacturability, and cost from day one.

Why CAD Matters in Manufacturing

CAD is more than drafting – it is engineering for real-world production. When done correctly, CAD can:

- Reduce production costs by optimizing materials and processes

- Shorten lead times by eliminating design flaws before fabrication

- Improve part performance, durability, and serviceability

- Streamline prototyping and revisions

- Ensure compatibility with downstream processes like welding, finishing, and assembly

By leveraging CAD early, we help clients avoid costly errors, achieve tighter tolerances, and improve overall quality.

Our CAD Services

1. Collaborative Design

We do not simply push drawings through software – we collaborate with you to ensure every feature works for manufacturing. Typical collaboration includes:

- Reviewing concepts for manufacturability and cost

- Suggesting design changes that reduce steps and materials

- Selecting best-fit materials and finishes for performance and environment

- Aligning specifications with your industry compliance needs

2. Design for Manufacturability – DFM

Our engineers apply DFM principles to every project so parts:

- Minimize material waste and scrap

- Require fewer secondary operations

- Are compatible with laser cutting and press brake forming, CNC machining, and powder coating

- Maintain structural integrity without unnecessary complexity

3. 3D Modeling and Visualization

We create detailed 3D models so you can visualize the final product before production begins. These models enable virtual fit checks, functional simulations, and photorealistic renderings for presentations or marketing.

4. Reverse Engineering

Have an existing part but no drawings? We can reverse-engineer it using precision measurement tools and recreate accurate CAD files that can be updated, modified, and re-manufactured.

5. Prototyping Support

CAD is integrated directly into our prototyping process. We iterate quickly based on real-world testing so you can validate form, fit, and function fast.

Integrated Manufacturing – From CAD to Finished Product

One of DSI’s strengths is taking a CAD file all the way to a finished, packaged product. Our integrated process includes:

- Design and Engineering – CAD and DFM optimization

- Fabrication and Machining – In-house precision manufacturing

- Finishing – Powder coating and other protective finishes

- Assembly – Mechanical and electromechanical integration

- Quality Assurance – ISO 9001:2015-certified inspection and testing

This full-service approach keeps your project in one place from start to finish – reducing lead times, cutting costs, and ensuring consistency.

Industries We Support With CAD

- Retail Fixtures and Displays – Durable, visually clean designs that install easily

- Medical Equipment – Precision housings and components engineered for cleanliness and compliance

- Electronics and Enclosures – Optimized internal layouts for airflow, wiring, and assembly

- Automotive and Transportation – Brackets, panels, and structural parts engineered for repeatability

- Construction and Industrial – Protective housings, control panels, and frameworks

- Energy and Agriculture – Rugged, field-ready components designed for serviceability

Quality-Driven Design

Our ISO 9001:2015 certification applies to the design stage as much as to manufacturing. Every CAD package is reviewed for:

- Dimensional accuracy and GD&T alignment

- Material suitability for the use environment

- Structural performance and safety factors

- Compliance with your industry standards

We also ensure CAD files integrate cleanly with CAM so there are no translation issues when parts move to production.

The Benefits of Partnering With DSI for CAD

- Manufacturing expertise built in – Designs are reviewed by engineers who understand production

- One-stop service – From CAD to finished product, all in-house

- Reduced lead times – Optimized designs move through the shop faster

- Cost savings – Avoid rework by addressing issues before production

- Scalable solutions – From a single prototype to full production runs

CAD FAQs

Can you work with my existing CAD files?

Yes. We accept common industry formats including SolidWorks, AutoCAD, STEP, and IGES files.

What if I only have a sketch or concept?

No problem. We can build your part from a hand drawing or idea and finalize the design with you.

Do you offer 3D printing for prototypes?

Our core prototyping is metal and plastic fabrication. For some applications we can arrange 3D printing as a supplemental step.

Will my designs be kept confidential?

Yes. We respect NDAs and maintain secure file handling for all customer designs.

Let’s Design Something Great

Whether you are developing a new product or optimizing an existing one, DSI’s CAD services ensure your project is engineered for success from day one. By integrating fabrication, machining, finishing, and assembly in one place, we help you bring better products to market faster and more cost-effectively.

Contact us to start your next design project and see how our CAD expertise can streamline your manufacturing.